Shrinkage and Silver Clay: What It Is and Why It Matters

As usual, this blog comes from a place of necessity — if you’re making items with silver clay, sooner or later, you’ll notice it shrinks. Silver clay shrinkage is just a fact of life when working with this material, and most of the time, it doesn’t cause any trouble. But there are moments when understanding silver clay shrinkage makes all the difference — and that’s exactly why I wrote this blog.

Side Note: This applies for all metal clays too, not just silver clay!

When does silver clay shrinkage matter?

Silver clay shrinkage really counts when you want your jewelry to be a specific size. Think rings, or setting a stone after firing — those types of projects require some careful calculations for silver clay shrinkage so everything fits perfectly.

The first (and most important) step is to determine YOUR personal silver clay shrinkage rate.

Even if a packet of clay mentions a typical shrinkage rate, I’d take that with a grain of salt. My experience has shown that shrinkage can vary quite a bit — even between batches. For example, ACS Fine Silver states on the package that it has a shrinkage rate of 8-9%, but when I tested it myself, I found it actually shrank by around 13%. That makes a big difference when you’re trying to set stones or fit pieces after firing.

How do I know my silver clay shrinkage? I did a simple test strip — and you should, too!

Here’s how

- Roll out your silver clay and cut a strip to a manageable length. It doesn’t have to be perfect, just long enough to measure before and after firing. I usually go for about 5cm. It’s easier to do the maths, and your measurements will be more accurate.

- Fire your silver clay strip using your usual firing schedule — whether at 800°C for 30 minutes, a hotter and longer fire, or your hand-firing method.

- After firing, measure the length again.

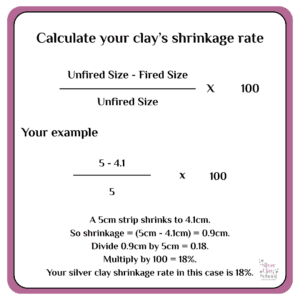

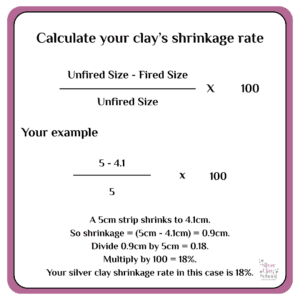

- Use this formula to find out your shrinkage rate:

Repeat this process for all your different clays and firing methods, and note your results somewhere safe — like a little notebook — so you can refer back whenever you need to.

Important: Retest only if you change your firing setup – i.e. youo change your torch or kiln

Making rings

When you create rings, you need to estimate how long your clay strip should be to wrap around a mandrel of the right size. Of course, you want your finished ring to be the perfect fit — so factoring in your shrinkage is key.

I always encourage my students to measure their finger directly rather than relying solely on a ring sizer. Ring sizers can be tricky and somewhat inconsistent, especially if you’re using a different sizing system. But using a simple formula, you can get a precise measurement every time.

Here’s how to calculate the length of the clay strip needed for your ring:

Stone setting

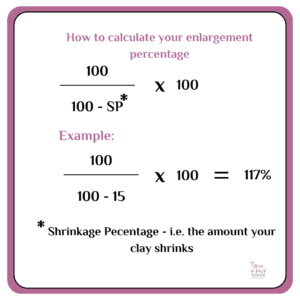

For setting stones, the approach is a little different. You need to calculate how much your design will enlarge so that, after firing, it shrinks down to the intended size.

Since you often enlarge your design with a photocopy before rolling out the clay, you’ll want to make sure your silver clay shrinkage is factored in during the design process.

Here’s the basic idea:

Design your piece slightly larger to compensate for shrinkage, ensuring your finished item fits perfectly.

If you’d like more detailed, step-by-step guidance on designing for stone settings, check out my Stone Setting on Demand module — it covers this process in detail.

The formula you’ll need to use:

To conclude

There you have it – three handy dandy silver clay shrinkage formulas you need in your life, if you work with any metal clay and you want to make rings, bracelets or stone settings that fit every time. I really hope you find it useful and if you do, you can get my free download, so you can print them out and save them for the next time you make something that needs to consider shrinkage in your design.

Master Silver Clay Shrinkage with this handy guide

0 Comments