How to reconsitute your Silver Clay

Being able to reconsitute your silver clay is a fundamental skill that every silver clay artist should have. It saves you money and gives you confidence when you set out to make something new. And it is really easy to reconsitute your silver clay!

When I started out, it seemed like a black art and my first instuctor wouldn’t share this ‘secret’ with me. Perhaps because she was a reseller of silver clay… She also made me believe that reconstituted silver clay was somehow substandard to clay fresh and new straight out the packet. Don’t even think about making any rings with it!

I am delighted to share how silver clay can be reconstituted in this blog. When I have a newbie in my School, they’re often concerned about the cost of silver clay and making mistakes. This is completely understandable because we are working with silver and it can be an expensive hobby.

You can also find an accompanying video on my YouTube channel which you can check out, if you’re more of a visual learner.

And while you’re at it, pop over to my other blog post ‘There is No Waste with Silver Clay’ if you need any more reassurance about using this wonderful medium and making mistakes ❤ .

So first things first…

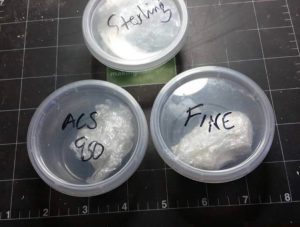

Keep your silver clay separated out into types.

This is the first rule for reconstitution. If you work with different types of clay – fine silver, sterling silver and enhanced silver which are the 950 and 960 mixes then make sure you have a different waste pot for each type. This is important for several reasons;

This is the first rule for reconstitution. If you work with different types of clay – fine silver, sterling silver and enhanced silver which are the 950 and 960 mixes then make sure you have a different waste pot for each type. This is important for several reasons;

- If you don’t and you reconstitute the clay without knowing exactly what it is, it makes it impossible to predict what it will do in the firing stage – some clays need higher temperatures to make sure they sinter properly. If you don’t know what you’re using, then you’ll not know which clays can be fired at a lower temperature when you’re firing glass, for example.

- The shrinkage for clays can vary – so again if you don’t know what you’ve reconstituted, then it becomes almost impossible to predict shrinkage accurately.

These rules become less important depending on the project you’re making and what you’re using to fire. So for example if you are using a kiln to fire and you don’t mind how much it shrinks or it doesn’t contain anything that can be damaged in a high temperature – think glass, sterling silver or gemstones, then you can mix your scrap together. If you’re more experienced and own a kiln, then you can just go for it. However, I’d advise caution otherwise.

How to reconstitute your silver clay

- Work in small batches to start off with until you get the hang of it!

Take your scrap clay and grind it down to a fine powder. You can use a pestle and mortar, a food processor or a coffee grinder for this purpose.

Take your scrap clay and grind it down to a fine powder. You can use a pestle and mortar, a food processor or a coffee grinder for this purpose.- Pass the powder through a very fine sieve. This allows you to separate the lumps and other things that may have been caught in the grinding process. I’ve found bits of wire and little stones I’ve missed – so remove any foreign items. You want to work with a fine powder. Put the larger lumps back into your scrap pot – they can be ground again or used to make silver clay paste.

Put the silver clay powder into a bowl. Take a water spray bottle and spray some water onto your clay. How much you use depends on how much powder you have but don’t saturate the powder, you want to add little and often.

Put the silver clay powder into a bowl. Take a water spray bottle and spray some water onto your clay. How much you use depends on how much powder you have but don’t saturate the powder, you want to add little and often.- Use a pallet knife and start to work the water into the clay by pressing the powder and the water together. You’re aiming for something that sticks together but isn’t too wet. Add more water if the mixture isn’t holding together. Repeat until you have a lump of clay which can be picked up.

Use an old plastic document folder. Coat both sides of the folder with release agent – olive oil or Cool Slip works well here. Place the lump of clay inside the wallet and close the wallet. Use a roller to roll the clay as flat as it can go.

Use an old plastic document folder. Coat both sides of the folder with release agent – olive oil or Cool Slip works well here. Place the lump of clay inside the wallet and close the wallet. Use a roller to roll the clay as flat as it can go.- Once the clay is flat, examine the surface. Use your spray water bottle to apply a little water to the surface of the clay. Then use your fingers to rub the water into the clay. Once the water has been absorbed, roll into a ball and repeat steps 6 and 7 until your clay looks shiny and hydrated.

- Wrap your clay up with some food wrap and put it into an airtight container. Leave it to rest for 12 hours or so.

- Use your malleable and reconstituted silver clay with a smug smile 😊 knowing you have saved a few pounds!

I hope this blog post helps you. I use my reconstituted clay to make all sorts of things, usually when I am working out new projects or having a play with new techniques. If I want a really high shine finish on a piece, I generally won’t use reconstituted clay – but for all other types of projects, it’s pretty good.

Happy reconstituting! Emma x

This is great! I’ve reconstituted the silver clay powder I save from sanding my projects. You do have to be careful to not add too much water to the powder. Go at it slowly.

It works perfectly and saves money. I’ve used my reconstituted clay for many new pieces of jewelry.